The machine includes featuring iHMI and high-speed, fine surface machining capabilities.

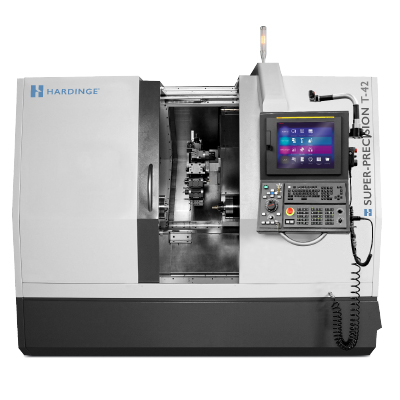

Hardinge Inc. has upgraded its Talent 42/51 multitasking CNC lathe. Designed to work with a variety of workholding systems, the upgraded lathe is said to provide machine shops with a highly versatile turning center, complete with a FANUC 0i-F Plus control.

The lathe offers a combination of features for accuracy, flexibility and durability in a compact design, the company says. The collet-ready main and subspindle are said to increase part accuracy and improve surface finish. The lathe features up to 12 axes, six spindle axes and two paths; up to two additional loader paths; and 4-axis simultaneous and 3+2 axis machining. It also offers multiple configurations, including live tooling, a Y axis and subspindle.

The lathe offers enhanced safety with an integrated FANUC Dual Check safety function. Shopfloor programming is conversational via Manual Guide i. The company says the lathe is highly customizable, with functions included for simple customization. It is said to offer high performance via an integrated high-speed Programmable Machine Control (PMC). Additional available functions include a high-speed and high-quality machining package.

Source: Production Machining