|

|

M-1 4X |

M-2 5X |

M-2 TM |

|

Lunghezza di tornitura |

1.200 mm |

1.200 mm |

1.200 mm |

|

Diametro mandrino |

up to 350 mm |

up to 350 mm |

up to 350 mm |

|

Max. Feed force W / X / Y / Z |

7,5 / 7,5 / 7,5 / 7,5 |

7,5 / 7,5 / 7,5 / 7,5 |

7,5 / 7,5 / 7,5 / 7,5 |

|

Working stroke X (top / bottom) |

200 / 200 mm |

200 / 200 mm |

500 / 200 mm |

|

Working stroke Y-axis |

210 (+130 / -80) mm |

210 (+130 / -80) mm |

210 (+130 / -80) mm |

|

Working stroke Z-axis |

1.100 / 1.200 mm |

1.100 / 1.200 mm |

1.200 / 1.200 mm |

|

Max. Travel speed W / X / Y / Z |

45 / 40 / 40 / 45 m/min |

45 / 40 / 40 / 45 m/min |

45 / 40 / 40 / 45 m/min |

|

Max. Peak distance |

1.200 mm |

1.200 mm |

1.200 mm |

|

Max. Speed |

6.000 rpm torque drive 10.000 rpm BMT / 12.000 rpm VDI speed drive |

6.000 rpm torque drive 10.000 rpm BMT / 12.000 rpm VDI speed drive |

12.000 (20.000) rpm |

|

Spindle bearing diameter |

120 (160) mm |

120 (160) mm |

120 (160) mm |

|

Dimensioni |

4.500 x 2.500 x 2.500 mm |

4.500 x 2.500 x 2.500 mm |

4.500 x 2.500 x 2.500 mm |

|

Peso |

12.500 kg |

13.500 kg |

15.000 kg |

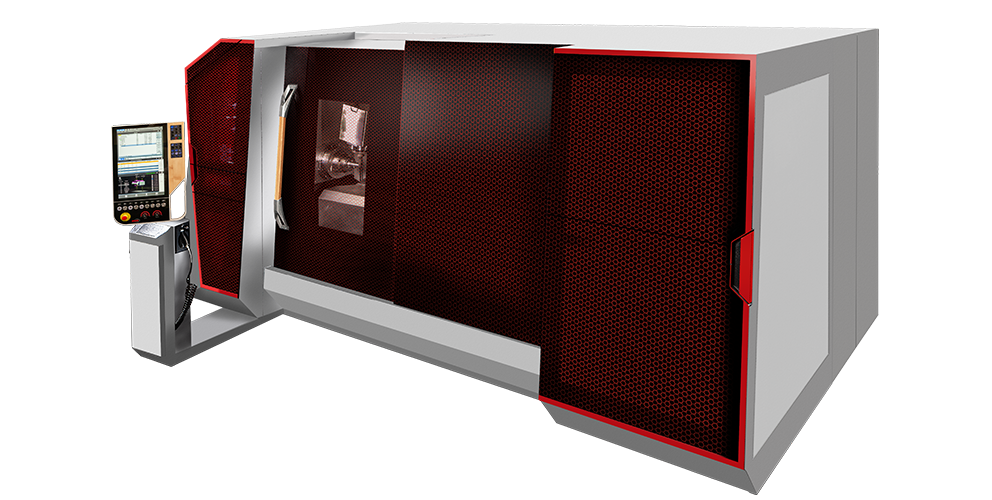

- Parallel turning or turning and milling.

- Design intuitivo e funzionale

- Ampia area di lavoro con ingombro ridotto

- Vibration-optimized design

- Accesso facilitato ai servizi a tutti i componenti rilevanti

- Generously equipped, swiveling control panel

- Vibration damping cast construction

- Long Z-axis for 1,200 mm machining length

- Y-axis (+130/-80 mm) with B-axis and milling spindle (HSK-T 63)

- Compact cartridge milling spindle (B-axis)

- Milling spindle with max. 20,000 min-1, power up to 20 kW, 100 Nm

- 38/102-cartridge chain magazine High-speed tool changer

- Complete machining from bars

- High stability and precision in machining of workpieces

- Identical main and counter spindle

In all configurations, parallel turning and milling from the bar is possible in addition to 6-sided complete machining.

Variant M-1 4X: Version has one tool carrier without counter spindle. Optionally, this version can be equipped with a tailstock and is suitable for medium-length to long shafts.

Variant M-2 5X: Version for multifunctional turning by 4-axis complete machining with two tool carriers, disc turret and counter spindle. Due to the two-turret arrangement, parallel work can be performed depending on the workpiece.

Variant M-2 TM: In this version, turning and milling from bar is possible through the B axis with a milling spindle as well as a tool carrier and counter spindle equipped with a disk turret.

6-sided complete machining

Due to its particularly long Z-axis, the ARTERY is very well suited for 6-sided complete bar machining or for long workpieces. Thanks to the compact milling head with HSK-T63 or optionally Capto C6 mounting, long tools can also be used on the face side.

Machining from bar

In addition to the 6-side complete machining, simultaneous turning and milling from bar with a diameter of up to 65 mm and 105 mm or workpieces with a turning length of up to 1.200 mm is possible.