|

|

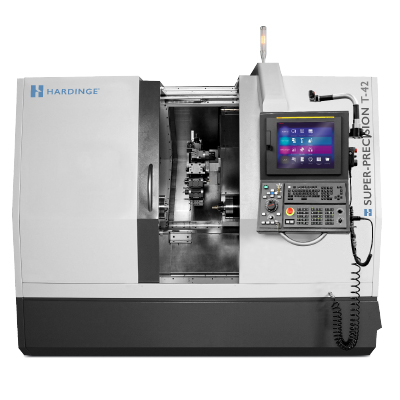

TALENT TT 42 |

TALENT TT 51 |

|

Naso mandrino |

A2-5 |

A2-6 |

|

Potenza nominale / Velocità del mandrino (max.) |

11 kW / 5.000 m-1 |

11 kW / 5.000 m-1 |

|

Lunghezza di lavorazione max. |

435 mm |

409 mm |

|

Diametro di lavorazione max. |

218 mm |

218 mm |

|

Capacità sbarra max. |

42 mm |

52 mm |

|

Numero di stazioni torretta (BMT45) |

16 stations |

16 stations |

|

Peso della macchina |

7,500 kg |

7,500 kg |

|

Dimensioni della macchina (L x P x A) |

3.669 mm x 2034 mm x 2.018 mm |

3.669 mm x 2.034 mm x 2.018 mm |

Twin spindles with C-axis contouring

- High strength, ductile cast iron headstock housings are hand scraped to the base for optimum stiffness, rigidity and vibration dampening

- Secondary spindle clamps the transferred workpiece for subsequent operations, can also be used as a tailstock with programmable torque control

- Large 90 mm front bearing bore provided excellent static and dynamic stiffness

- Low-inertia hydraulic disk brakes provide superior clamping power for live tooling operations

- Adjustable Hydraulic actuators for use with collets and jaw chucks

- Spindle bearings are protected with air purge and labyrinth seal systems

- Exacting part roundness and surface finish capabilities

– Less than 1 μ

– Less than 0,8 μ Ra

- Twin precision spindles with ANSI A2-5” (TT42) or A2-6” (TT51) models and A2-5” on the secondary spindle

- Powerful spindle drive packages

– 11 kW on TT42 and TT51

- Up to 6.000 rpm (TT42) and 5.000 rpm (TT51) speed range on both spindles allow exact synchronization for part transfers

- High torque ratings

– 91 Nm on TT42

– 105 Nm on TT51

- A single timing style drive belt is used for power transmission from the spindle motor to the spindle

- Accurate part transfer – within 0,012 mm between spindles

- C axis contouring with 0,001° degree positioning on both spindles for live tooling applications

- Large availability of spindle tooling from Hardinge, the world leader in work holding

– Flex C systems

– Collets and collet adaption chucks

– Expanding collet systems

– 3 jaw chuck systems

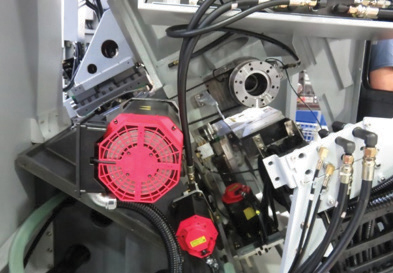

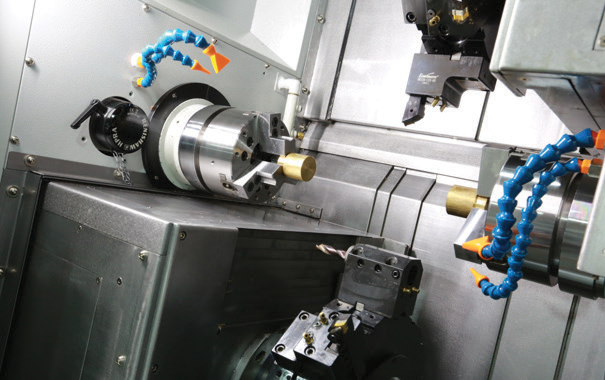

Twin turrets with live tooling capability

- Twin 16 station turrets can be used on either spindle or both spindles simultaneously. Every turret station is live capable

- High-speed bidirectional indexing (0,69 second station to station) keeps non-cut time to a minimum

- Rigid turrets accurately lock into place within 0,12 μ

- Easier processing of parts families and fewer setups due to large number of tooling stations

- Industry standard BMT-45 DIN 1809 peripheral munt tooling system

- Multiple tools can be mounted on a single station to increase tool capacity

- Wide range of optional BMT-45 tool holders are available from Hardinge featuring coolant nozzles or thru-tool coolant capabilities

- Powerful live tooling capability on all stations for radial and axial milling \ drilling operations

– 5,5 kW power rating

– 23,8 Nm torque rating

– 5.000 rpm maximum speed

– Optional Live tooling attachments up to 20.000 rpm

- Standard Y axis on the top turret with helical interpolation function

- Rigid tapping capability , all spindles is standard

- Angular workpiece machining is easily accomplished using angular adjustable BMT-45 DIN 1809 live tooling attachments

- Digitally-controlled servo motors on all axes are superior for positioning accuracy and stiffness

- Fast rapid traverse rates on all axes provide for reduced non-cut time

– 24 m\min on X, X2 and Y axes

– 40 m\min on Z, Z2 and secondary spindle axes

- Powerful 2,78 kW axis drive motors

- Parts removal system (conveyor-type)

- Parts removal system (through secondary spindle)

- Live tooling attachments

- Tool touch-off system

- Part present detector (secondary spindle)

- Chip conveyor

- Y-axis (upper turret only)

- Spindle tooling

- Thru-spindle air blast (secondary spindle)

- Thru-spindle coolant

Additional options

- Auto door

- Coolant chiller

- Bar feed systems

- Power transformers

- Stack light

FANUC OiTF

The Hardinge TT Series of multi-tasking turning centers features a custom designed CNC with dual processing power, speed and ease of operation to get the most out of your turning center! Experienced CNC users will appreciate fast machining cycles with the Oi Plus controls powerful 64 Bit dual processing capabilities. Program both the main and secondary spindles for simultaneous machining — synchronized spindles assure smooth part transfer. C-Axis and spindle orient on both spindles accommodate complex machining. Synchronization of the tapping axis and spindle rotation allows the use of rigidly-mounted taps. A split-screen 15” LCD display is helpful during setup for viewing of positions, distances-to-go, and programs all on a single screen. The background programming feature allows you to load the next program “off-line” while the machine is busing producing parts. A simulated, graphic toolpath display verifies correctness of each step of the operator’s program. Full complement of standard features for maximum performance — very few options needed!

General

- Two pair of interpolating axes

- Inch / metric selection by G-code

- Programmable resolution .001”/.001mm

- Tool offset capability .001”/.001mm

- 160 meters part program storage

- Part program storage (320, 640 or 1,280 meters total)